17

2025

-

03

Heading towards the sea, becoming stronger: Shandong Lanrun Group paints a 'blue answer sheet' for comprehensive rural revitalization with seaweed

As the first rays of early spring sunlight fall on the sea level, the waters near Rongcheng City, Weihai City, present a busy scene of harvest. Ten thousand mu of seaweed are entering their spring harvest season. Taking advantage of the fine weather, fishermen are stepping up their efforts to harvest and process seaweed, starting their annual seaweed harvest.

This small seaweed, from the initial cultivation stage to subsequent processing and sales, has formed an integrated industrial structure in Rongcheng. Seaweed processing enterprises, led by Shandong Lanrun Group, have taken root in Rongcheng. By introducing advanced processing equipment, they process fresh seaweed into various market-popular products such as sushi nori, sandwich nori, and seasoned nori, meeting the needs of different consumers. These nori products are not only popular in major cities across China but also exported to overseas markets, gaining the favor of international consumers.

Prioritizing Ecology, Building a Blue Sea Granary

The selection of seaweed cultivation bases is extremely meticulous. The Rongcheng waters, traversed by the 37° North Latitude line, have clear and pure seawater year-round, rich in calcium, magnesium, zinc, and other minerals and trace elements that are extremely beneficial to seaweed growth. The salinity and temperature are also consistently maintained within the optimal range for seaweed growth, providing natural conditions for the healthy growth of seaweed.

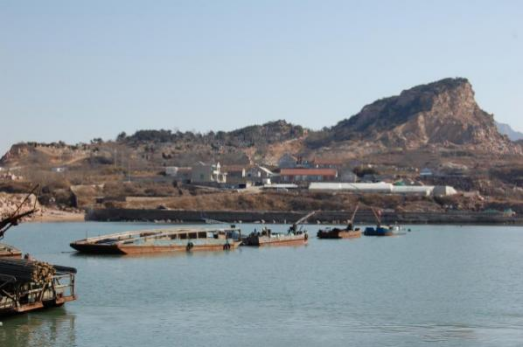

Located in Renhe Town, Rongcheng City, the Haicheng Algae Industry Cultivation Base is one of the large seaweed cultivation bases in the area and one of the raw material suppliers for Shandong Lanrun Group's nori products. Rows of ropes connect one floating ball after another, outlining neat "fields." Here, an innovative practice of "blue carbon ecology" is being demonstrated—establishing a three-dimensional ecological aquaculture model of "algae-shellfish-fish": seaweed is cultivated in the upper layer, shellfish in the middle layer, and artificial reefs at the bottom. Seaweed, shellfish, and fish form a symbiotic system: seaweed releases oxygen through photosynthesis, shellfish filter feed on plankton to purify the water, and artificial reefs absorb settling organic matter, forming a closed ecological chain. According to calculations by the Chinese Academy of Fishery Sciences, this model increases the ocean's carbon sequestration capacity by 40%, reduces the nitrogen and phosphorus content in the water by 60%, and effectively reduces the incidence of red tides, truly achieving "storing grain in the sea and fixing carbon in algae."

To improve aquaculture efficiency and resource utilization, Rongcheng City has innovatively developed a "Porphyra—Pyropia—Ulva prolifera" rotation cultivation model. Porphyra is heat-resistant and suitable for summer cultivation; Pyropia is suitable for cultivation from autumn to the following spring. Through this rotation model, marine resources can be fully utilized, effectively avoiding the impact of seawater nutrient dilution on seaweed quality and yield.

Industrial prosperity activates "a pool of spring water." The deputy secretary of the Renhe Town Party Committee introduced: "After aquaculture enterprises like Haicheng Algae Industry invest and build factories in Renhe Town, on the one hand, through the siphon effect, they attract marine aquaculture and land-based seaweed processing enterprises, driving regional employment. Local fishermen leverage their own advantages to engage in seaweed cultivation and harvesting at their doorstep; women workers are responsible for sorting seaweed raw materials, drying kelp packaging, and their per capita income has significantly increased compared to before. On the other hand, this model further optimizes the marine aquaculture structure of Renhe Town, extending the original single kelp cultivation to seaweed-related industries, making the marine aquaculture species more abundant. This provides strong support for Renhe Town to accelerate the construction of marine ranches and blue granaries, help the marine industry grow, and promote high-quality integrated development of the primary, secondary, and tertiary industries."

Fine Processing, Lanrun Leads Products Overseas

Although seaweed cultivation was successful, due to a lack of processing and sales channels, seaweed could only be sold as raw materials at low prices, and the income of farmers was unsatisfactory. A person in charge of a local seaweed distributor calculated an account: 1 ton of seaweed, using primary processing technology to produce dried seaweed, has a market value of about 60,000 yuan; however, through deep processing, the added value of the product can be increased by 20 times. However, the domestic market share of seaweed is limited, and export is the commercial blue ocean for the seaweed industry.

Under the coordination of the local government, Lanrun Group invested 500 million yuan to revitalize an idle factory area in Lidi Town, significantly shortening the project preparation period and seizing the opportunity for rapid industrial development. Faced with industrial workshops that did not originally meet food processing conditions, under the guidance of relevant departments, Lanrun Group carried out comprehensive renovations to the workshops. From the careful planning of the workshop layout to the strict selection of materials for floor paving, and the scientific design of the production process, all were built according to the highest industry standards, laying a solid foundation for high-quality seaweed processing.

Entering the seaweed processing workshop of Lanrun Group, five intelligent seaweed processing production lines are operating at full capacity. Sheet after sheet of initially processed seaweed raw materials, after undergoing fine processes such as screening, baking, seasoning, dehumidification, and packaging, are transformed into sushi nori commonly seen in Japanese cuisine. The intelligent production process not only greatly improves the production efficiency of baked nori but also guarantees product quality and safety from the source. At the same time, under the careful guidance of customs, Lanrun Group has established a complete food safety assurance system, creating a full-chain quality and safety supervision and prevention line from raw materials to products, ensuring that every piece of nori exported is of high quality.

Today, Lanrun Group's exported nori products have successfully obtained multiple international authoritative certifications and are sold in more than 20 countries and regions. Through its own efforts and innovation, Lanrun Group has not only expanded the international market map for Rongcheng seaweed but also injected strong impetus into the development of the local seaweed industry, driving the coordinated development of upstream and downstream industries, and allowing Rongcheng seaweed to truly take center stage on the world stage.

In order to facilitate the international sales of Rongcheng seaweed products, Rongcheng Customs conducts in-depth "physical examinations" of enterprises through verification and daily supervision and management to ensure the effective operation of the enterprise's quality system. In terms of seaweed customs clearance, customs adopts convenient measures such as priority inspection, testing and certification, paperless customs clearance, and holiday appointments to facilitate enterprises to "report, inspect, and release immediately" and flexibly arrange product exports.

Strive for Maritime Strength, Create a "Blue Answer Sheet" for Comprehensive Rural Revitalization

Rongcheng City, following the thinking of the industrial chain, focuses on cultivating new impetus for the marine industry and building a "deep blue city" that strives for maritime strength. Focusing on 17 key marine industry projects with an investment of 1.463 billion yuan, it accelerates the integrated development of the primary, secondary, and tertiary marine industries, integrates kelp, seaweed, and abalone aquaculture resources, and accelerates the transformation from "raw material Origin" to "trading center," with an expected annual transaction volume exceeding 500,000 tons.

Relevant officials said that Rongcheng City will also use the seaweed industry as an opportunity to further promote the development of the marine industry and create a new national "golden coast" industrial highland that thrives by facing the sea. Lanrun Group will also continue to play a leading role in this blue ocean, writing more glorious chapters.

Excerpt from China.com.cn

Lanrun Group, a subsidiary of Shandong Xinfakong Holding Co., Ltd., is a marine food group enterprise integrating marine food processing, research and development of marine functional products, and cold storage, processing, and sales of aquatic products. Main products include frozen prepared foods, canned tuna series, ultra-low temperature tuna products, frozen seafood such as squid, leisure food series, tuna collagen peptide, kelp, seaweed, and compound seasonings, among others. It is a certified enterprise of China's Green Food Certification.

Key words:

Other dynamics

2025-05-17